During the manufacturing process, many medical devices or equipment for use on humans must be sterilized according to recognized standards. This includes gowns, surgical drapes, syringes, and implantable medical devices. In fact, the United States has a huge medical device sterilization industry, regulated by the U.S. Food and Drug Administration. The industry is expected to grow considerably in the coming years.

The most common medical device sterilization methods will unlikely be able to handle that continued growth, say experts in the field. In addition, the industry is looking for alternatives since the two leading technologies use substances—ethylene oxide and cobalt-60—that present safety issues.

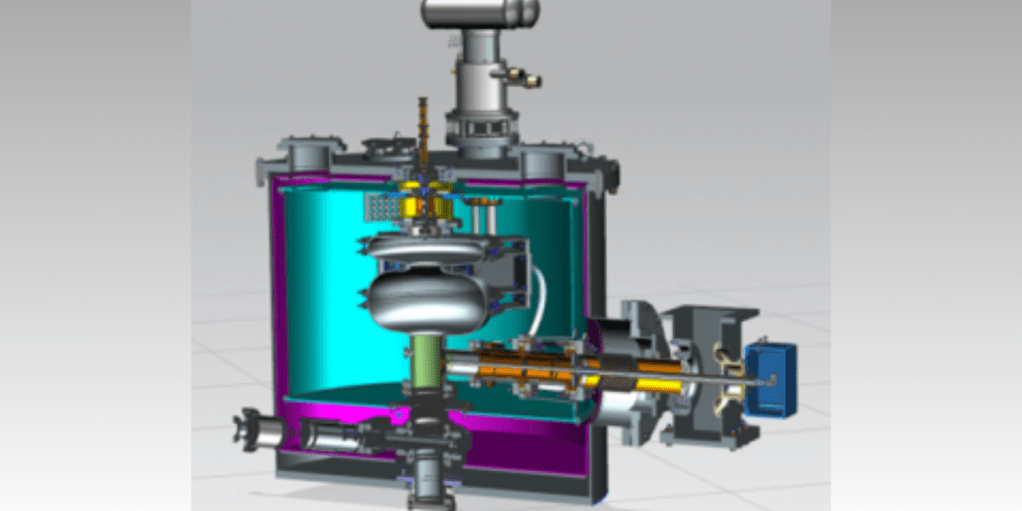

Researchers at the U.S. Department of Energy’s Fermi National Accelerator Laboratory believe they can help. Using funding provided by the National Nuclear Security Administration, Fermilab researchers are building a prototype electron beam accelerator that integrates four emerging accelerator technologies into a single, efficient accelerator system. Industrial partners could use such a machine to make X-rays for sterilizing equipment.

“The focus of our effort is to develop a high-power electron beam that can serve as an alternative to large-scale cobalt facilities,” said Thomas Kroc, applications physicist and principal investigator of the Fermilab medical device sterilization efforts. “In doing that, we exploit the superconducting accelerator experience that we developed here at Fermilab. We think that technology provides the efficiency that makes it feasible to run electron accelerators that can sterilize medical equipment as well as existing large facilities that use other methods.”