Introduction

In the early morning of April 7, 1776, after fighting through the night, Capt. John Barry and his crew threw ladders over the deck of the HMS Edward and took command—the first capture of a British ship by the Continental Army [1]. Long before that day, and ever since, ladders have been a staple tool of naval and land assault. They also find a place in other critical environments, including tactical military and special operations, emergency and disaster response, police and SWAT operations, climbing, and diving. Over the last several decades, military and first responder communities have continued to improve and refine ladder design and weight for deployment and small unit operations. Here we review the state of the art in assault ladder materials and design and consider where future development efforts should be directed. Studies by Deft Dynamics LLC find that ladders fabricated from composite materials provide decreased weight at a cost of increased stowed volume. There is ample room for innovation in this space, to reduce both the collapsed size and weight of a composite ladder.

Assault ladder technologies fall into one of two categories: self-supporting (rigid) or caving/Jacob’s (wire, rope, or cable). Assault ladders typically collapse into short sections for easy carry and are used for entering buildings and bridging across natural or urban rifts. Caving ladders, often fabricated from steel or Kevlar cables, can be used in descent/ascent/extraction operations. Caving ladders remain the primary platform for extraction and emergency response and currently provide little room for new/novel developments. However, advances in different materials offer the defense and first responder communities potentially game-changing improvements in self-supporting ladder technology.

Performance Metrics

Improvements in ladder technology primarily focus on the reach, collapsed size, and weight of ladder designs. The Department of Defense (DoD) and first responders classify and compare tactical ladders by their performance along two metrics: reach-to-weight ratio and reach to-collapsed-size ratio. A ladder’s reach-to-weight ratio is its fully extended reach divided by the weight of its segments. A high ratio in this metric is important when the ladder must be moved into place by hand or carried long distances. A ladder’s reach-to-collapsed-size ratio is its fully extended reach divided by its largest segment or collapsed dimension. A high ratio in this metric is important for storage in a vehicle or vessel prior to deployment or when the ladder is transported directly by the operator as a part of his or her gear.

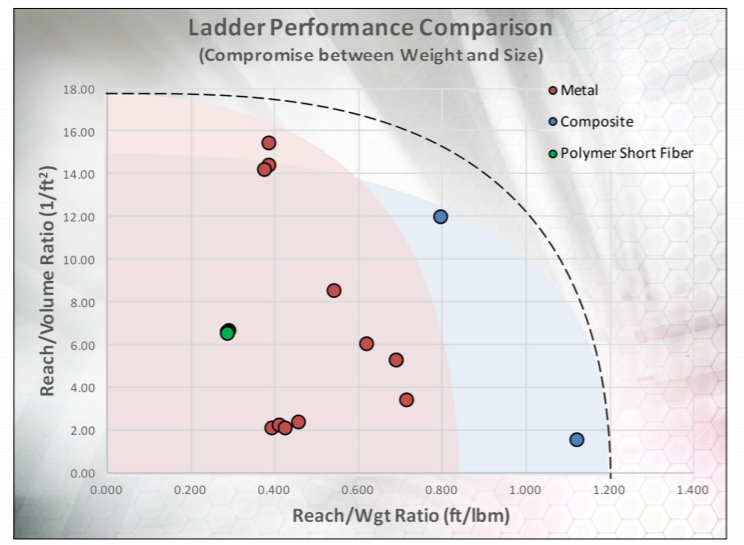

A Deft Dynamics performance comparison of commercially available self-supporting ladders is shown in Figure 1. The current limits of assault ladder performance are bounded by a reach-to-volume ratio of nearly 16 (here, measured in feet per cubic foot). The best designs are extraordinarily collapsible based on their ability to fold into a compact package, such as the Safariland Group Tactical Portal Ladder [2]. On the outer limit of possible reach-to-weight ratios, carbon composite ladders excel with a peak

of 1.12 (feet per pound mass), such as the Atlas Devices REBS Carbon Multi Ladder [3]. However, despite their low weight, these carbon fiber ladders do notcollapse into a compact package. It is a

common feature of composite ladders that they typically come in larger, monolithic designs. Figure 1 reinforces the fact that achieving a high reach-to-volume ratio is driven by mechanical design—easily achieved with aluminum—whereas a high reach-to-weight ratio is achieved bythe use of innovative materials. Carbon fiber composites have paved the way for many new designs that improve the

weight and strength characteristics of a ladder; however, in general, the use ofcarbon fiber composites prevents a small collapsed size. New and more modular composite methods and materials, such

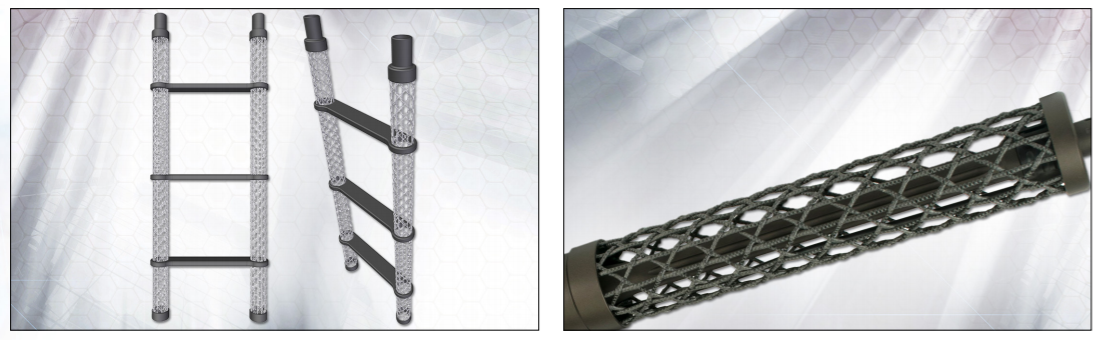

as open-architecture composite structures (O-ACS), may be key to pushing past current limitations in assault ladder design (see Figure 2) [4-8].

Figure 1: State-of-the-art ladders present a compromise between low weight and small collapsed size. Carbon composites push the frontier toward lower weight but are not as compact when stowed as the best metal designs.

Figure 2: (left) Deft Dynamics LLC open-architecture composite ladder segment (design concept). Figure 3: (right) Deft Dynamics LLC open-architecture composite structures currently being used in the field as handguards for the M4 rifle.

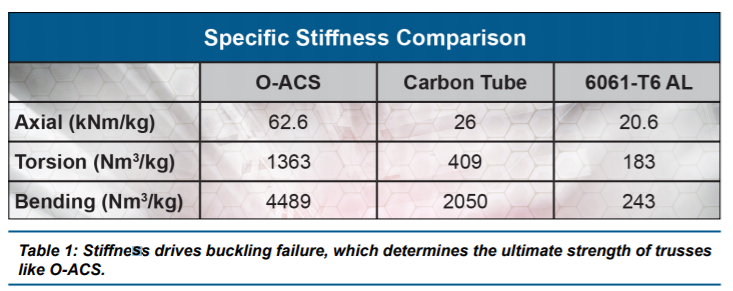

With the goal of advancing the capabilities of composite materials and designs, Deft Dynamics has designed and implemented O-ACS structures for rugged use applications, including an M4 rifle handguard, which is currently being used in the field (see Figure 3). The breakpoints for these

structures (fabricated in 15-inch segments) show great potential for use in assault ladder applications (see Table 1). Deft Dynamics has built proprietary software, Fellpoint, which accurately simulates and predicts O-ACS strength. Innovations in composites that reduce a ladder’s collapsed size must

focus on composite structural member interconnections, while also remembering that ultralight composites lend themselves well to large outer diameters. This can be achieved most easily by focusing on nested or telescoping structures, as has been successfully employed by some metal ladder manufacturers [9].

Summary

With an understanding of DoD and first responder requirements, two key metrics (reach-to-weight and collapsed-size-toweight ratios) provide a clear method for comparing the raw performance of assault

ladders. However, no existing ladder model achieves both weight and collapsed-volume design goals simultaneously.

Though valuable for design targets, these performance metrics do not perfectly capture all the benefits or pitfalls of a given ladder design. Certain situations may require shorter assembly time or quieter

operations during ascent. The assault ladders compared here may not provide sufficient support for bridging long distances.

A successful high-value clandestine operation may demand the use of an extremely compact ladder, regardless of weight, and rescue operations often occur in abnormally high or low temperatures.

Keeping these considerations in mind, the defense and first responder communities could incorporate composite materials into superior collapsible designs for next-generation assault ladders to lighten

warfighter load and improve tactical and response operations.

References

1. History.com Staff. (2009). U.S. Navy captures first British warship. Retrieved from http://www.history.com/this-day-in-history/us-navy-captures-first-british-warship

2. The Safariland Group. Tactical Portal Ladder. Retrieved from http://www.safariland.com/products/body-armor/tactical-body-armor-and-gear/tactical-accessories/ladders/tactical-portal-ladder-TAC_PORT_LADDER.html

3. Atlas Devices. (n.d.). REBS Carbon Multi Ladder [Fact Sheet]. Retrieved from https://atlasdevices.com/wp-content/uploads/REBS-carbon-multi-ladder-factsheet.pdf

4. Gurley, A., Beale, D., Broughton, R., & Branscomb, D. (2015). The design of optimal lattice structures manufactured by maypole braiding. Journal of Mechanical Design, 137(10), 101401.

doi:10.1115/1.4031122

5. Broughton, R., & Gurley, A. (2016, May). Connecting textile and composites; Open architecture braided composite truss structures. Paper presented at JEC Americas, Atlanta, GA.

6. Gurley, A., Branscomb, D., Broughton, R., & Beale, D. (2014, October). Rapid design of minimal-weight open-structure composite beams. Paper presented at the Composites and Advanced Materials Expo, Orlando, FL.

7. Branscomb, D., Broughton, R., Beale, D., & Gurley, A. (2014, April). Robust pre-impregnated yarn for manufacturing textile composites. Paper presented at the AATCC International Conference, Asheville, NC.

8. Branscomb, D., Gurley, A., Beale, D., & Broughton, R. (2012). Open-architecture composite tube: Design and manufacture [Abstract] (pp. 169-170). Poster presented at the Fiber Society Fall Meeting and Technical Conference, Boston, MA. Retrieved from http://www.thefibersociety.org/Portals/0/Past%20Conferences/2012_Fall_Abstracts.pdf

9. Telesteps. (n.d.). Retrieved from http://telesteps.net/